Why does repeatability matter?

No matter what stage of development an LED or laser device is in, it’s going to go through multiple rounds of testing to ensure that each part has been manufactured correctly. Some manufacturers also test their devices in multiple labs around the world.

As long as measurements between labs and across development stages match, production can continue and improvements can be made to devices. However, when there is variation from one measurement to the next, several issues can occur.

A lack of measurement repeatability increases time to market and can lead to a number of devices being binned incorrectly, effectively leaving money on the table. To improve repeatability the source of the measurement error must first be identified. Potential culprits include the device itself, test equipment, operator error, or something else entirely.

In the video above, we focus on test equipment, specifically current sources, as our error source and discuss how you can optimize the equipment in your lab to improve repeatability.

What to Look for in a Current Source

To maximize measurement repeatability, look for a current source or source measure unit that has a minimal amount of fixed error. Your current source or source measure unit should also have precision timing, accurate triggering, and be capable of producing fast pulses (preferably 50µs or shorter).

Test Case: Pulsed Source Measure Unit

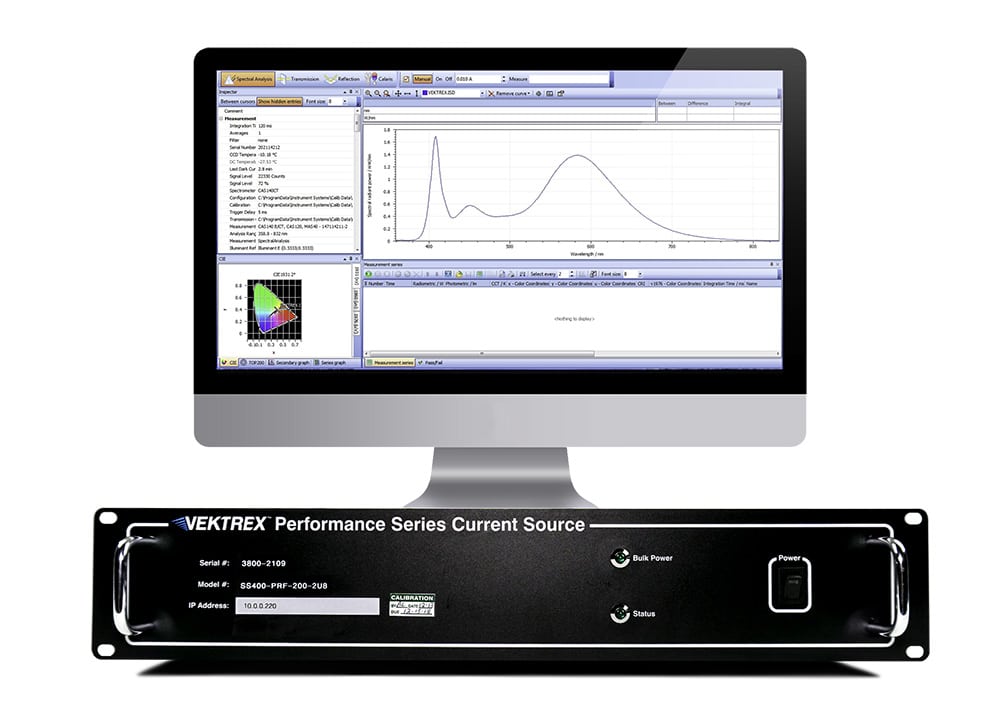

We tested an LED using a SpikeSafe Performance Series Current Source, an Instrument Systems CAS 140 spectrometer, and SpecWin Pro software.

For this test, we powered the device with continuous pulse mode at a pulse width of 50µs (which is sufficient to limit dynamic self-heating effects). As you can see in the video, each measurement was nearly identical to the previous one, showing excellent measurement repeatability.

Using the Vektrex light measurement system, you can achieve repeatable measurements within 0.05%. Contact us to get the ideal current source for your test setup and improve your measurement repeatability.