A Pulsed Source Measure Unit Built For LED and Lasers, With Unmatched Power, Pulsing, and Measurement Capability

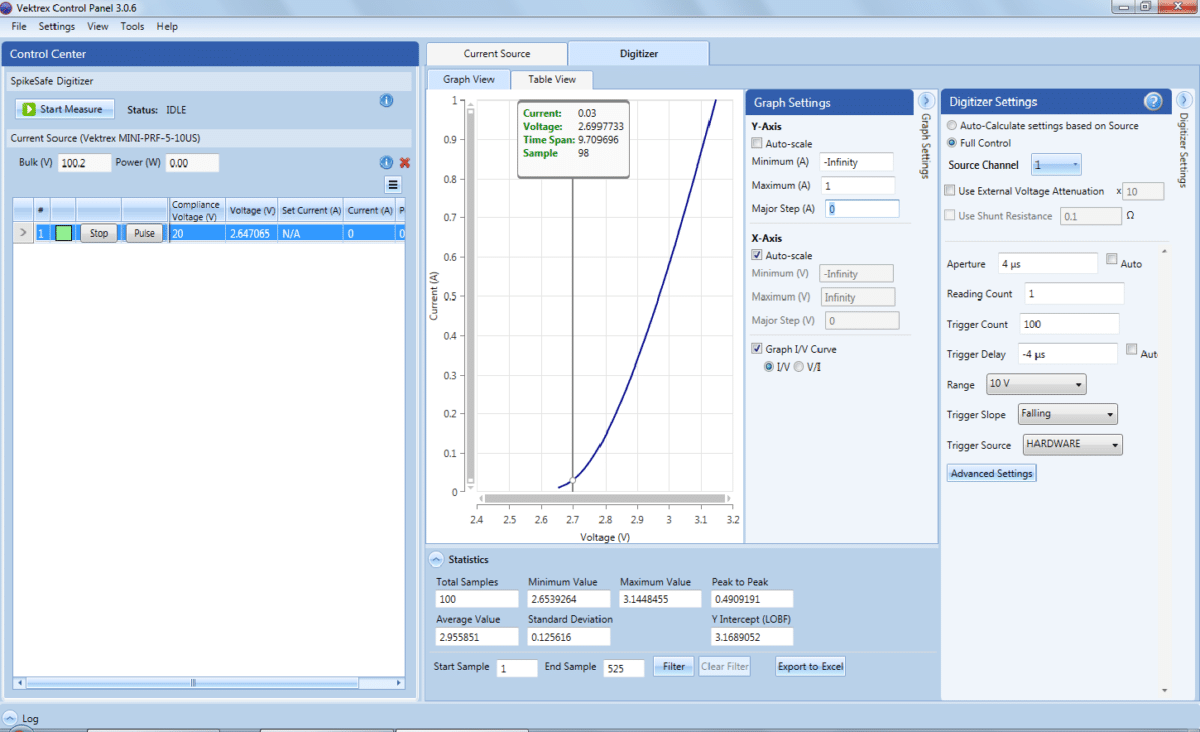

The SpikeSafe Source Measure Unit is a precision pulsed source measure unit that precisely sources pulsed current and simultaneously digitizes voltage. Optimized for precise and repeatable high-power LED and laser testing, SpikeSafe™ SMU (Source Measure Unit) current sources deliver precise pulsing with low microsecond rise times, low-jitter triggering and integrated digitizer for more accurate and repeatable high-power LED and laser testing. Combined with Vektrex easy-to-use Control Panel software application, use the fast pulse Source Measure Unit to quickly and easily sweep and generate IV curves.

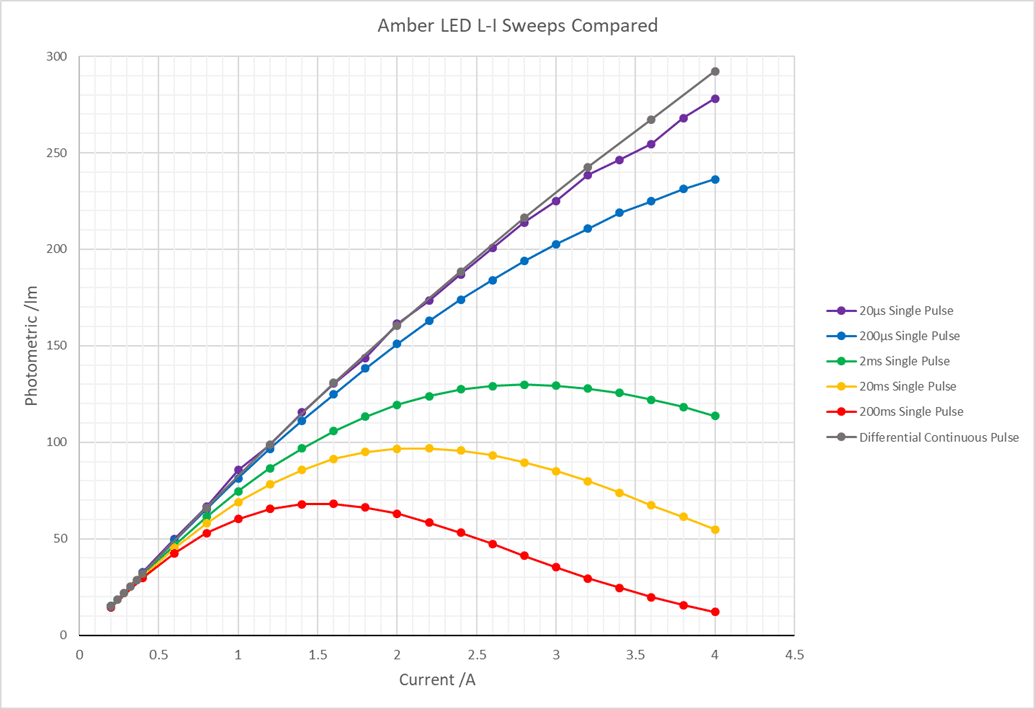

Device junction heating distorts measurements, causing L-I curves to droop and shifting I-V curves. With Vektrex’s fast pulsing SMUs you can make your measurements before heat builds up, revealing true device characteristics.

The SpikeSafe SMUs feature general operational modes including DC, Continuous Pulse, Single Pulse. Specialized operational modes including Sweep, Burst, Repetitive Burst and others are hardware integrated for ease of use. Minimum pulse widths as low as 1us reduce junction temperatures for VCSEL, laser diode and other semiconductor devices. Using Vektrex’s proprietary continuous-power-conversion technology, a single SpikeSafe SMU can easily power a broad range of devices with sustained output power and no duty cycle limitations — at voltages well above the 10V to 60V limitation of general-purpose pulsed SMUs.

Use the information below to compare models and determine the maximum current that is appropriate for your application.

HIGH CURRENT SMU FOR CURRENT >= 10A

Go to the High Current SMU page to learn more about the SMU for applications where current >= 10A.

SMU FOR CURRENT <=10A

Select maximum current for your application from the table below to learn more.

| Maximum Current | Details |

|---|---|

| 10A | SMU with integrated low noise digitizer. 10A maximum current Short pulse 01us, 10us and 50us. Fast rise/fall time 200ns for square pulse |

| 5A | Precision Source Measure Unit Maximum current 5A Current accuracy 0.04% + 175μA 600W total output power |

| 4A | Ideal for 3W devices 4A maximum current. DC and precision pulsed current 600W total output power |

| 500mA | SMU Ideal for low current applications Minimum current 10 micro-amps Fast pulse capability |

| 50mA | SMU designed for micro-LED Minimum current 06uA |

Test What You Couldn’t See

With more and more high-power density LED and laser devices coming to market, there’s a gap between what can tested with traditional source measure units and present engineering and production testing needs. Inadequate power, pulsing and measurement capabilities limit previous-generation source measure units.

SpikeSafe® SMU precision pulsed source measure units close that gap by providing accurate pulsing from hundreds of seconds down to 1us with sustained output power. SpikeSafe SMU combines the speed and power needed for LED and laser testing with integrated high-speed digitizing measurement. Now you can accurately test what you previously couldn’t test, and see what you didn’t have the power to see – with remarkable repeatability.

Introducing “Crazy Stable” Measurements

SpikeSafe SMUs provide the power needed for more accurate, efficient, and repeatable measurements.

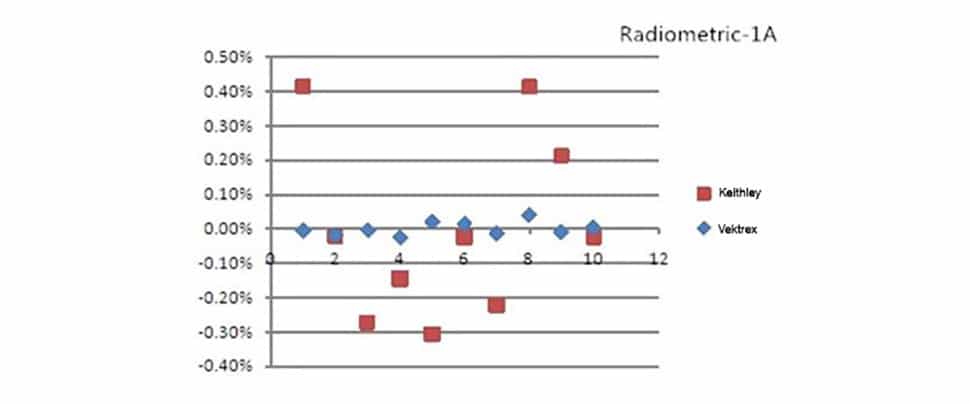

Submicrosecond to low microsecond rise/fall times, programmable load tuning and on-the-fly pulse width correction combined mean the device under test experiences less heating and more uniform heating. The result is unmatched measurement stability – measurements one beta site evaluator described as “crazy stable”.

With measurement stability, multiple measurements and averaging are not required. With measurement stability, false positives and false negatives are eliminated, improving yield and reducing the cost of test.

True Differential Digitizer

Vektrex’s SMU uses advanced true-differential digitizer technology to produce time-aligned measurements required by measurement standards. Common mode noise present with other measurement technologies is greatly reduced. This means the SMU can measure small VF changes such as a 200uV shift in a high-voltage LED.

The SMU digitizer samples continuously providing single or multiple measurements that are boxcar averaged. This approach eliminates the need for external signal processing to obtain a measurement.

Get Test Flexibility with Force Sense Selector Switch

The SpikeSafe SMU Force Sense Selector Switch supplies integrated Connect/Disconnect and A/B Switch functions.

Critical for high-speed production environments, the connect/disconnect function is a true isolated switch that rapidly disconnects power to test devices, eliminating control steps and speeding testing.

A/B Switch functions allow secondary instruments to share load wiring with the SMU. Secondary instruments may provide low current and reverse voltage measurements. With many secondary instruments available and currently in use, the A/B switch function enables these instruments to be used in parallel with Vektrex SMU. For example, use Vektrex SMU for higher currents, higher output power, faster pulsing, and better measurements. Use secondary instruments for reverse voltage and pico cur.

Pulsed SMUs support a wide range of applications. With continuous power conversion, MCV above 10V is possible. Select from the maximum currents below.

Easy-to-Use Control Panel Software Application

Vektrex’s easy-to-use Control Panel Software Application provides turn-key control of the SMU along with external source-measure units, high-speed sampling voltmeters and spectrometers. Control Panel’s intuitive test tools and graphic displays support common optoelectronic tests such as LI sweeps, slope efficiency testing and junction temperature measurement.