Vektrex announces release of Pulsed Sweep functions now available with SpikeSafe™ Performance Series Current Sources and Pulsed Source Measure Units.

Leveraging Vektrex’s repeatable, near-perfect, square pulse capability, the addition of the Pulsed Sweep function makes Performance Series Current Sources and Pulsed Source Measure Units a more-complete solution. Hardware-integrated Pulsed Sweeps execute faster than traditional staircase sweeps and greatly reduce device heating, allowing high-power devices to be tested without the need for active cooling.

Performance Series Current Sources that include the Bias upgrade will also be capable of an industry-first, integrated Pulsed Sweep with Bias. Pulsed Sweep with Bias allows junction temperature (Tj) and forward voltage (Vf) to be measured after each pulse, producing invaluable data and graphs that reduce time to market for devices.

All SpikeSafe Pulsed Source Measure Units are equipped with this function. SpikeSafe Performance Series Current Sources ordered after August 2017 will include these new functions.

Pulsed Sweeps

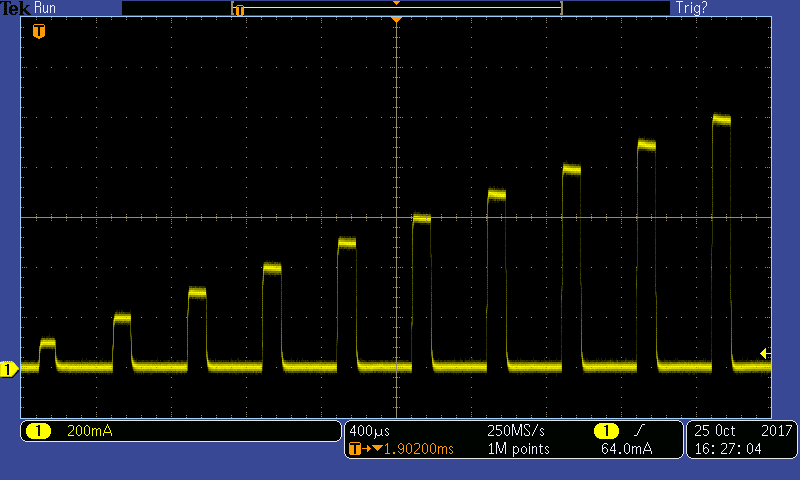

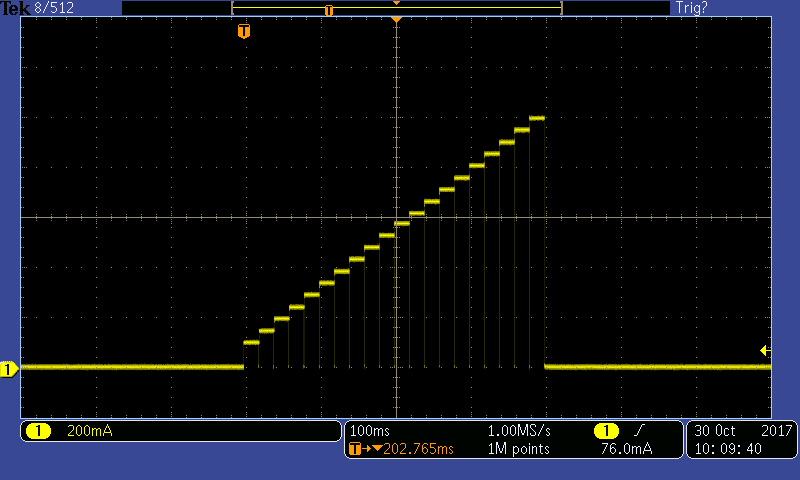

The Pulsed Sweep function outputs a specific number of current pulses of increasing or decreasing amplitude. Pulses may be as short as 10µs. Pulsed Sweeps improve the accuracy and execution time of common device tests such as voltage vs current plots, light vs current plots, and maximum pulse withstand tests.

Hardware-Based Timing Improves Repeatability

The SpikeSafe’s hardware-based timing precisely aligns voltmeter or spectrometer measurements to the current pulses. This precision alignment means sweep plots are perfectly repeatable without the variations seen with source-measure instruments that utilize firmware-based timing systems.

Short Pulses Reduce Heating, Improving Accuracy

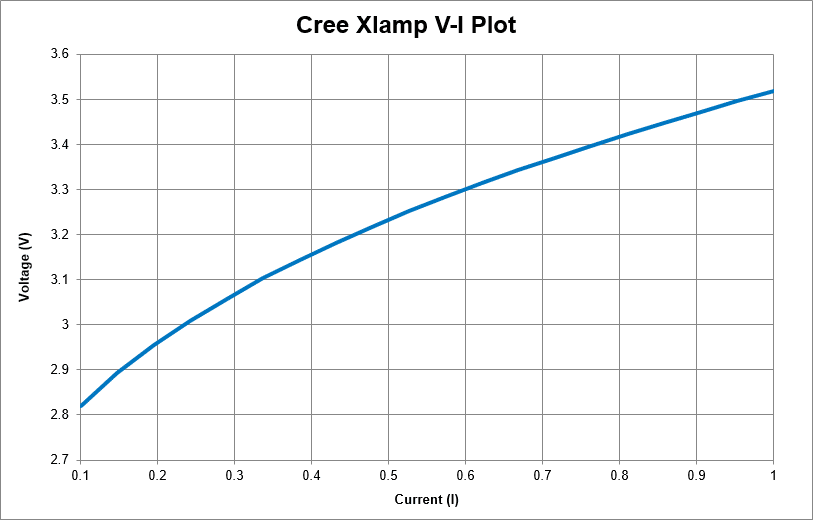

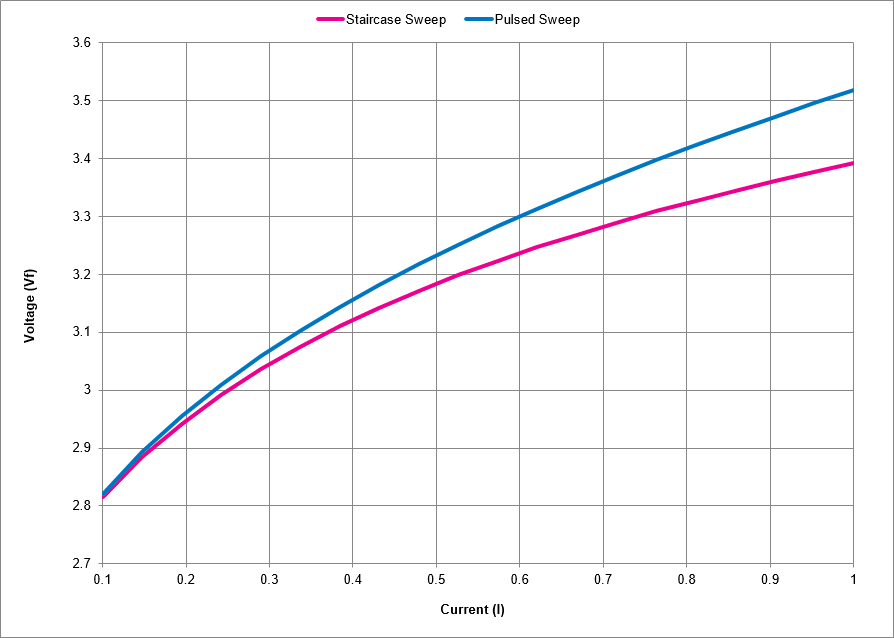

Utilizing Pulsed Sweeps instead of the typical staircase sweeps found in source-measure instruments greatly reduces device junction heating during testing. This means high-power devices may be tested without using active cooling. It also means plots generated with Pulsed Sweeps show reduced droop at high currents, meaning a more accurate plot overall.

Emulates Staircase Sweeps for Compatibility

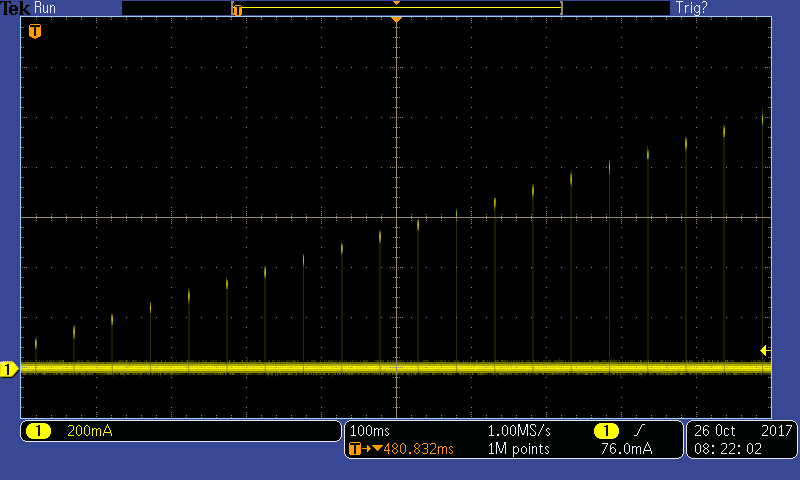

While Pulsed Sweeps more accurately show device characteristics, sometimes it is necessary to duplicate measurements made with previous-generation source-measure instruments that employ non-pulsed or “staircase” sweeps. Staircase sweeps induce significant junction heating, so the measurements made with them don’t match a typical pulsed sweep measurement. To replicate these measurements, the SpikeSafe’s pulsed sweep may be programmed with long on times and very short off times. The resulting waveform duplicates staircase sweep junction heating, enabling direct comparison of old and new measurements.

Optimize Sweep Speed Using Sweep with Bias Mode

The industry’s first Pulsed Sweep with Bias current mode combines a Pulsed Sweep with a DC bias current. The bias current keeps the semiconductor junction forward biased between pulses so that its forward voltage may be measured. Changes in this voltage correspond to changes in temperature. Plots of this post-pulse forward voltage are easily generated and viewed using the SpikeSafe Control Panel software application.

Simplify Pulse Withstand Testing with Failure Level Capture

Sometimes sweeps are used for destructive testing or current-limit testing. For example, an LED’s pulse withstand capability may be tested using a pulsed sweep that extends above the device’s absolute maximum pulsed current. This type of testing is supported in two ways – by allowing higher output and capturing the actual current level at the moment of failure and report this current level via a SCPI error message.

Contact us to request more information and a quote.