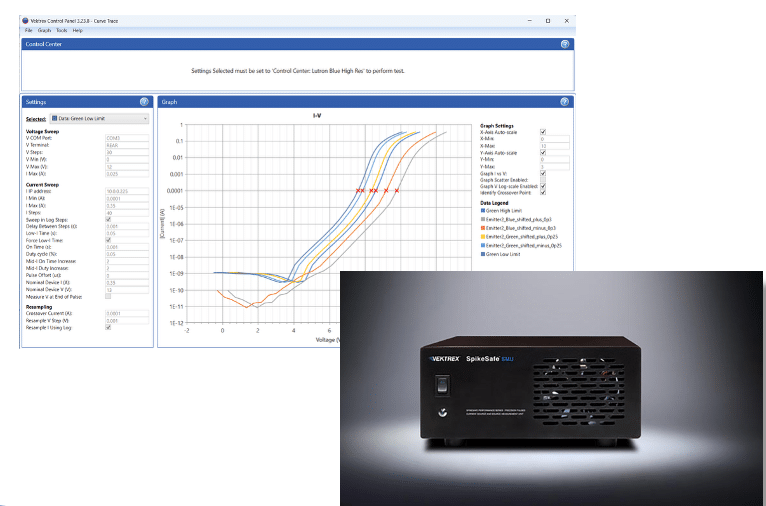

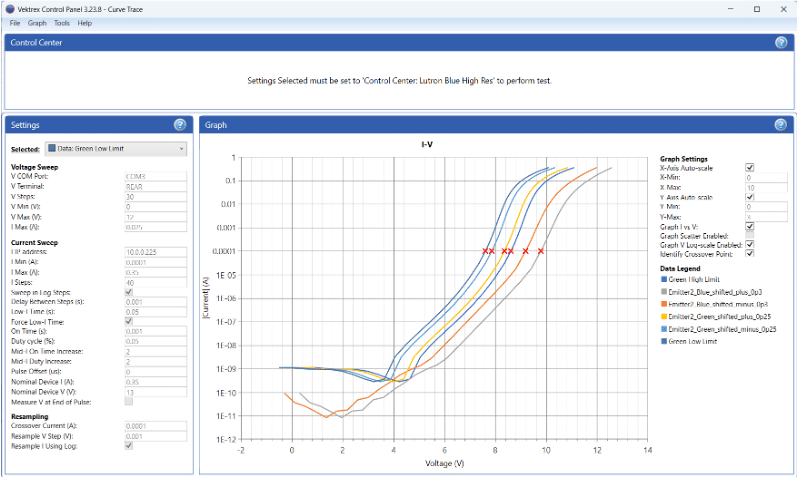

Vektrex curve trace tool combines low-current constant-voltage measurements transitioning to pulsed current measurements at higher currents. The novel hybrid curve trace approach provides optimized diagnostic coverage across device failure modes. It offers increased accuracy and allows testing at higher currents safely.

The curve trace tool software application offers extreme flexibility including sweep parameters such as start and end voltage/current, pulse times, transition from low current to high current points and data management. Easily generate pass fail limit lines for manual pass fail device verification.

For many devices, it is useful to understand performance at very low currents in the microamps (for example, below laser threshold), and also at much higher typical operating currents, often amps or tens of amps. These two testing regions have very different testing requirements.

Low current performance is best determined using a constant-voltage sweep. A positive voltage is applied to the device, and the voltage is increased slowly while the current is measured. Because of circuit capacitances, this type of sweep must be executed slowly to allow time for the capacitances to charge.

High current performance has different requirements. Constant-voltage operation is risky as a small increase in voltage can result in too much current being driven through the device, so constant-current sweeps are preferred. In addition, significant power is transferred to the device under test, so this type of sweep must be performed quickly to limit device heating.

The instrumentation used for these sweeps generally is optimized for either low or high-current testing. General-purpose SMUs are optimized for slow, precise low-current measurements. While they can perform higher current measurements, test times are long and heating is significant.

To provide “the best of both worlds,” Vektrex’s new Hybrid Sweep software implements a constant-voltage sweep at low currents and a constant-current pulsed sweep at higher currents. The data from both tests is combined into one graph.

For applications requiring failure detction at very low currents, Vektrex recommends use of the integrated switch combined with another SMU – for example a Keithley 2400 series.

For more information please email info@vektrex.com.