Solutions from Vektrex address specific application needs for LED and Laser manufacturers within our areas of expertise including LM-80, LM-85, Light Measurement applications, Reliability for LEDs and Lasers, Burn-In, load boards and custom burn-in fixtures and accessories. Our system solutions include LM-80 systems for LEDs, COB, LED modules, Automated Light Measurement Systems, Light Measurement Systems integrated with Instrument Systems CAS Spectrometers and others, Reliability and Burn-in Systems for LEDs, VCSEL, and Lasers and more. Vektrex has a full team of engineers to support your system needs including software and fixturing. Please contact Vektrex to discuss your needs.

Thermal Measurement – Vektrex

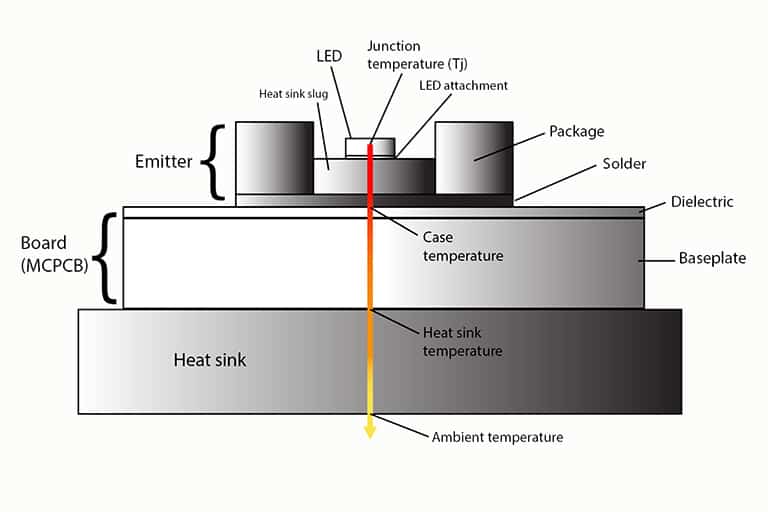

Thermal measurements are used in a variety of applications involving LEDs, laser diodes and other semiconductor devices. Specifically junction temperature, is useful at all stages of semiconductor production from design and development to quality assurance. The basis for every semiconductor data sheet and end user design is junction temperature.

Light Measurements – Vektrex

Vektrex Vektrex light measurement solutions offer precise repeatable measurements. Applicable for laser, LED, UV LED, VCSEL and other current driven devices, the systems are based upon Vektrex SMU and our partner photometric instrumentation and spheres.

Burn-in Test System

Vektrex offers a Burn-in Test System to enable small capacity reliability and burn-in test. Flexible and modular with 8 individually controlled source channels, this benchtop system is ideal for small capacity applications including

- applications test

- burn-in and validate vendor devices

- burn-in devices prior to taking thermal measurements

- reliability test for R&D

- Pre LM-80 test

Use to drive your devices in your form-factor with your thermal control your test mode and your computer at your workstation.

Learn more about the Laser Burn-In Test System

LED Reliability Test System

Vektrex is the leading supplier of LED reliability and burn-in test systems. Vektrex systems populate facilities world-wide supporting reliability test of LEDs and other semiconductor devices.

LM-80 Test and Measurement Equipment