The Vektrex Integrated Thermal Control System (ITCS) uses proprietary water-based thermal control to maintain consistent LED and laser device temperatures during high power testing applications. LED/VCSEL manufacturers and third-party test facilities standardize on ITCS chambers for their testing needs.

Temperature uniformity is essential to successful high power device testing. The Vektrex Integrated Thermal Control System (ITCS) circulates water at a precise temperature in a closed-loop system for uniform thermal control in a compact footprint.

With up to 10kW of power handling capability – at operating temperatures up to 150C – the ITCS chamber provides the flexibility to test numerous high power device types in a single chamber and maintain temperature uniformity within 2C. The ITCS can be purchased as a stand-alone product or with additional Vektrex components.

Temperature Uniformity Within 2°C

LM-80 thermal control systems with tightly-regulated temperature uniformity are essential to the successful LM-80 testing of LEDs, modules, arrays, COB, high power devices, mid power devices, and low power devices.

With up to 10kW of power handling capability – at operating temperatures up to 150C – the ITCS chamber provides the flexibility to test numerous high power device types in a single chamber and maintain temperature uniformity within 2C.

Vektrex LM-80 Chamber Features

- Up to 10kW heat dissipation, temperatures to 150C

- Energy-efficient thermal control using plant water

- Tcase, Tambient, and Tsink monitoring and data logging

- Isolated thermocouples

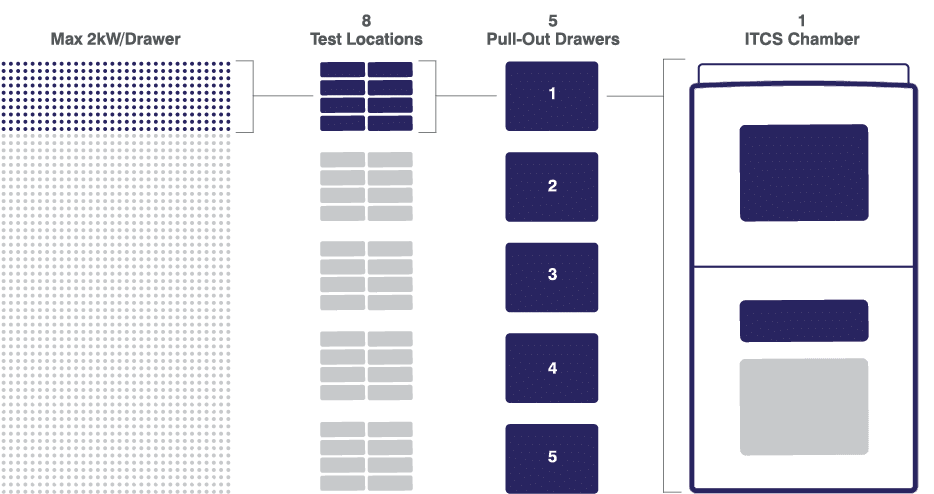

- Capacity – 40 load boards; up to 1,600 devices

- Five slide-out drawers, easy load and unload

- NVLAP auditable and traceable

- Calibration and validation certificates

- Worldwide install base

- Contaminant-free construction

- No VOC producing components used

- Factory acceptance testing to ensure ITCS does not contaminate devices

Modular and Expandable System Architecture