UV LED measurements require a source to power the LED and an optical measurement device (photodiode, spectrometer, etc.) to measure the light. Vektrex makes a variety of Precision Pulsed Source/Measure Units (SMUs) optimized for UV LED measurement. We offer software and complete turnkey systems for accurate electro-optical measurements.

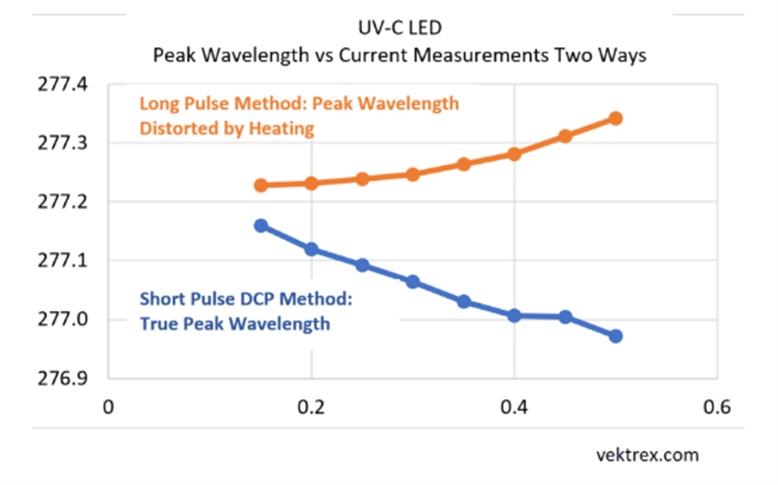

The graphic below shows how a UV-C LED’s peak wavelength changes with current. If this LED is measured with DC-like long pulses, the peak wavelength seems to increase with current. But the actual characteristic, seen with short pulse testing, is a decreasing trend. With Vektrex SMU, short pulse measurements are possible and can be used to see the true device characteristics.

SMU Key Features for UV-LED Measurement

- Short pulse for better measurements (10us recommended)

- Optimized for LM92 DCP measurement reducing post processing math

- Component to pair with your favorite light measurement device

- Software to simplify and automate LM92 measurements

- Available as a complete UV-LED Measurement system

Contact Vektrex to learn more about how to get accurate electro-optical measurements.

How to Power UV LEDs for Measurement

Vektrex Pulsed SMUs meet the requirement for testing UV-A, UV-B, and UV-C LEDs with short pulses. In fact, the Vektrex SMU was used extensively in research that led to the development of the ANSI/IES UV-LED Measurement standard, LM-92-22. LM-92-22 specifies pulses of 10 µs and 20 µs, and a technique called Differential Continuous Pulse.

To power your device, connect the SpikeSafe SMU using the supplied force/sense cables. Then use Vektrex developed Control Panel software application to connect, configure and control the SMU. Define the pulsed current mode, pulse parameters and digitizer settings. The LED’s forward voltage is measured with the SMU’s smart digitizer, which automatically aligns measurements with the current pulse. Trigger in and trigger out signals are available to synchronize current pulses with external instruments to capture the light. Visually validate your UV-LED measurement.

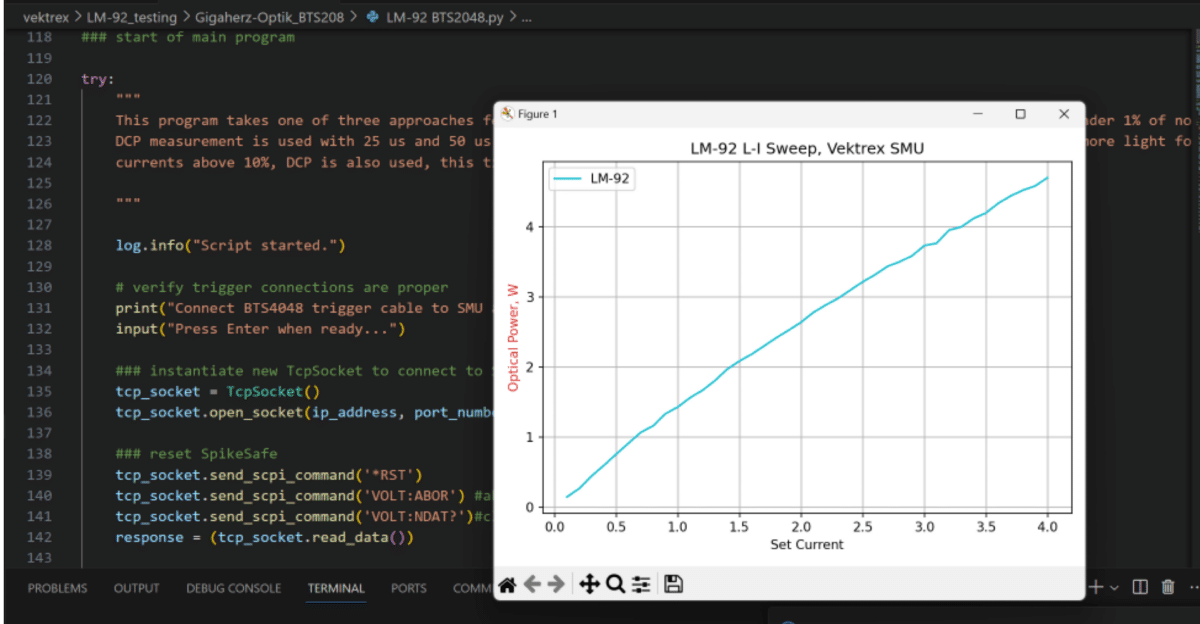

Software to perform LM92 DCP Measurements

Leverage the power of LM92 and the Differential Continuous Pulse method for accurate electro-optical measurements using Vektrex software.

Learn more about the UV-LED Measurement software

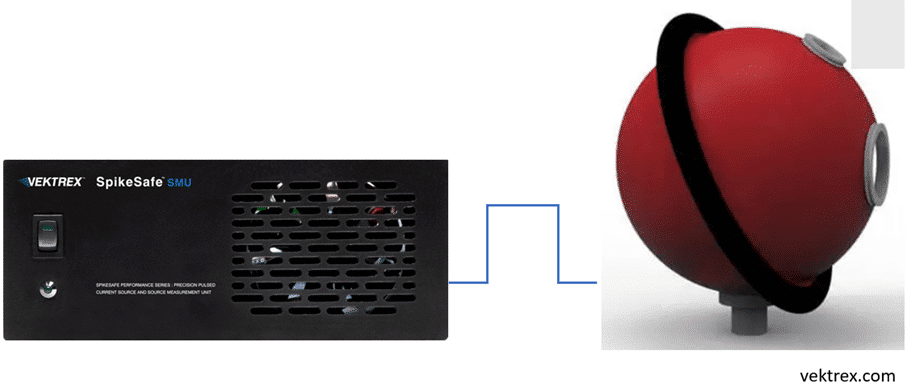

Turn-key UV-LED Measurement and Characterization System

If you need more than a power source and software, Vektrex partners with companies to supply a full UV-LED measurement system including PTFE sphere, spectroradiometer, SMU, software, cables, and the needed accessories to support UV measurements and characterization.

Learn More About the DCP LED Test Station

Vektrex SMU Features That Differentiate Us

- Clean, low-jitter pulsing from 1 µs to DC

- True-differential digitizer automatically aligns measurements to pulse

- Voltages above 10V – up to 180V

- Currents up to 60A

- Low or high duty cycle operation, 0-100%

- High average output power, >500W

Short-Pulse-LED-Measurement Research

To learn more about the science behind short pulse testing, here are some useful references:

- Short Pulses for Better Measurements: This article, authored by Jeff Hulett, explains why short pulses will achieve more accurate optical measurements.

- Simplify Short Pulse Test Implementation: Published in LEDs Magazine, Jeff Hulett explains how a new short-pulse test method has advanced spectrometer and source/measure instrument capabilities used in electro-optical measurements of LEDs.

- Use Fast Precise Pulsed SMU to Characterize LED Droop: LED products are typically characterized using methods that increase device heating. These outdated methods, using DC current, long pulses or staircase sweeps result in temperature droop.

- UV-LED Thyristor Effect The thyristor effect is a known shortcoming of immature LED products. See differences in UV-LED measurements for mature and immature devices.

Standardized UV-LED Measurements

Optimum methods for implementing UV-LED short pulse tests are documented in ANSI/IES LM-92. LM-92’s methods explain how to use techniques like DCP to overcome thermal, optical, and electrical challenges UV parts present. Standardized measurements ensure your measurements will agree with measurements taken at other labs. They also provide authoritative proof your product will deliver the advertised power, providing effective germicidal disinfection.

To learn more about Standardized UV-LED Measurements refer to:

Optical Metrology and Documentary Standards for GUV Radiation Sources: Read the full article authored by Jeff Hulett, Cameron Miller (NIST), and Yuqin Zong (NIST) in UV Solutions Magazine.

- NIST, IUVA, and Vektrex Collaboration Produces LM-92 UV LED Testing Standard: Jeff Hulett, Cameron Miller, and Troy Cowan detail the importance of cross-organization participation in UV standards development and how those efforts will further market penetration and performance of GUV devices.

- LM-80-21 Release Improves Testing Methodology: LM-80-21 improves testing methodology for visible LED devices and addresses applicability to new classes of devices, including UV LEDs, laser diodes and filament LEDs

- Mean Differential Continuous Pulse Method for Accurate Optical Measurements of Light-Emitting Diodes and Laser Diodes: NIST publication related to methods for accurate optical measurements of LEDs and Laser Diodes.

- Factors to Consider with UV Measurements: LEDs Magazine webinar featuring Intertek and Vektrex.

- Practical Implementation and Applications of DCP Measurements: The new Differential Continuous Pulse (DCP) measurement method is a powerful tool that can speed and simplify challenging LED and laser optical measurements.