The Problem with Averaging Measurements

Commonly used source/measure units produce varied measurements that require averaging to be useful. This raises the cost of measurements and adds additional risk to the production process as it can mask both operator and equipment errors.

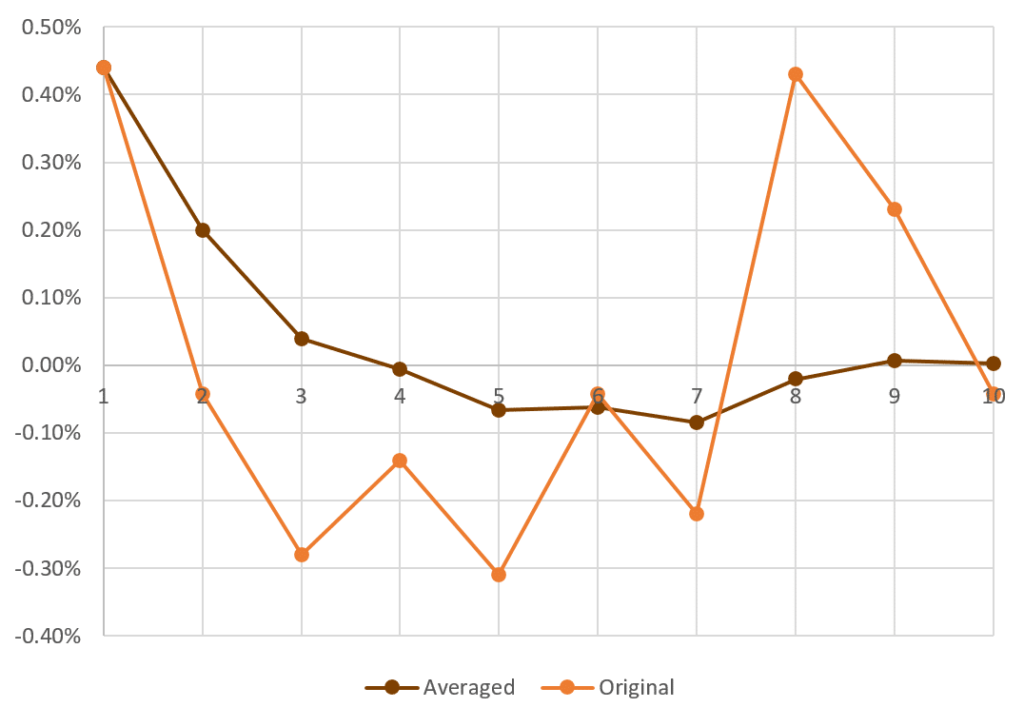

The following graph shows one manufacturer’s measurements taken using a Keithley 2401 unit and a CAS-140 spectrometer.

The original measurements (bright orange line) vary by about 0.8% which is significant when testing the flux output of a production LED. In order for these measurements to be usable, the manufacturer had to average them (dark line).

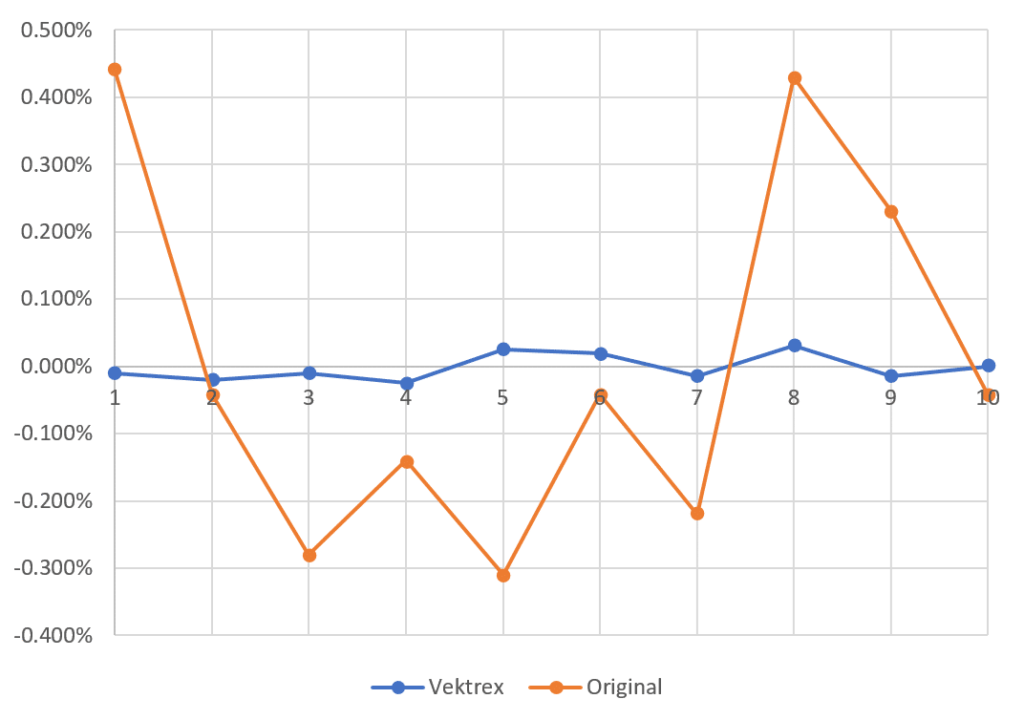

This same manufacturer swapped out their Keithley unit for a SpikeSafe™ Performance Series Current Source and took the same measurements using the SpikeSafe and CAS-140.

As you can see in the overlaid graph, the SpikeSafe produced much more consistent measurements with only 0.04% measurement variation.

Save Time and Money by Switching to SpikeSafe

[table id=15 /]

The Bottom Line

By switching to a Performance Series Current Source, this manufacturer was able to go from taking 10 measurements per DUT to taking just 1.

The immediate benefits of this were as follows.

- Increase capacity without increasing labor cost

- Increase capacity without significant investment

- Increase yield with reduced measurement variation

Contact us today to see how you can benefit from switching to SpikeSafe.