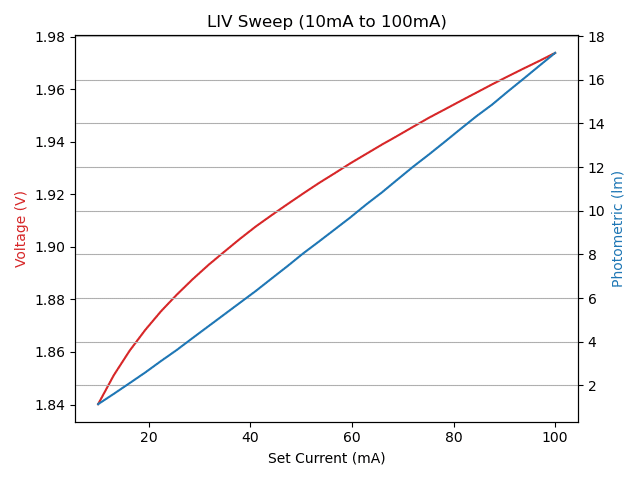

LIV testing is a fast and simple method of determining the key performance parameters of light emitting devices such as laser diodes, LEDs and VCSEL. It combines two measurement curves in one graphic. You can think about it as an IV curve with the addition of light measurement. The LIV test data below was generated using VEKTREX’s Source Measure Unit combined with a spectrometer or photodiode. To generate this curve the SMU sweeps current from 10mA to 100mA using time-aligned measurements to read voltage and lumen output. Email info@vektrex.com to get more information about using the SMU for your LIV testing.

How to Purchase an LIV Test System

What is LIV Testing?

Properly known as a light-current-voltage (LIV) sweep, LIV testing efficiently and accurately assesses the performance of a laser diode or other light emitting device. LIV testing brings together two curves into one graph; an LI curve and an VI curve. The LI curve (light and current) shows the device optical light intensity at the applied current. The IV curve shows the device voltage at the applied current.

Results help identify potential abnormalities, assist with quality control during manufacturing and help establish efficiency for laser diodes. Testing may also factor in performance at different temperatures that can impact the performance and reliability of the laser diode and the end product.

An LIV test requires two key instruments; a source measurement device (e.g. SMU) for applying current and assessing voltage and a light measurement method including photodiodes, spectroradiometers and other similar instruments.

For a LIV test, lasers are placed in a controlled environment, where current is applied in a sweep, with voltage measured at the sweep interval and at the same time measuring the light output. For best results the three variables, light, voltage and current, must be time aligned.

LIV testing is used for

- Testing the reliability of light emitting devices in various conditions that could affect their lifespan or the design of an end product

- Test device performance – for example output, wavelength, output power – after manufacturing

- Identifying performance impacting defects.

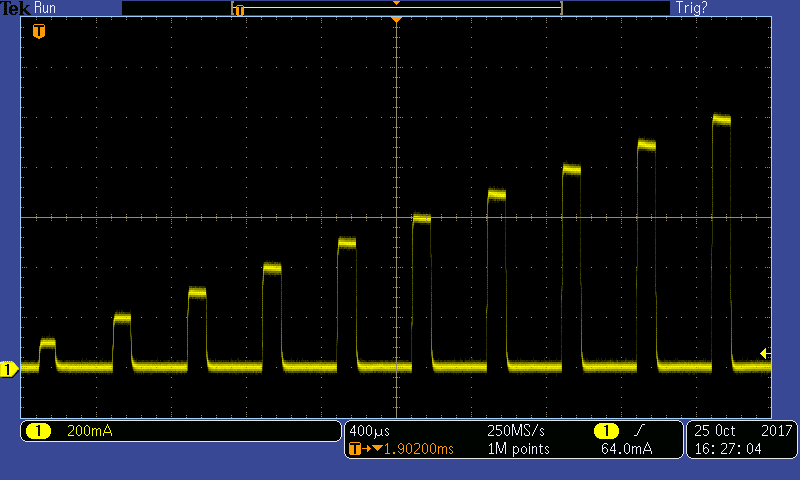

Use A Pulsed Sweep For LIV Test

With pulsed sweeps, the current amplitude is increased in steps and voltage or other measurements are made at each step. With pulsed sweeps, device heating is reduced and cumulative heating may be avoided. With pulsed sweeps, high power devices may be tested without the need for active cooling.

Python API and Examples

Python API and examples allow you to worry less about the code and more about the science of LED and Laser testing. VEKTREX offers many options to quickly automate testing of LEDs and Lasers.

Source Measure Unit For LIV Curve

The SpikeSafe SMU is a precision pulsed source measure unit that precisely sources pulsed current and simultaneously digitizes voltage. Optimized for precise and repeatable high-power LED and laser testing, SpikeSafe™ SMU (Source Measure Unit) current sources deliver precise pulsing with low microsecond rise times, low-jitter triggering and integrated digitizer for more accurate and repeatable high-power LED and laser diode testing.

Video: How to Generate an IV Curve Easily

Generating an IV Curve easily is possible with the SpikeSafe SMU, a pulsed source measure unit. No special equipment, programming or sequence code is required. Easily validate vendor IV Curves to ensure your product development and research efforts are efficient. In this video, you will learn how to generate a High Power IV Curve using the SpikeSafe Pulsed Source Measure Unit.